Arick Nitzsche

Manufacturing engineering

Hometown: Phoenix, Arizona, United States

Graduation date: Fall 2026

FURI | Fall 2024

Development of Multi-Material Micro-Structures by Using Micro Continuous Interface Printing (µCLIP)

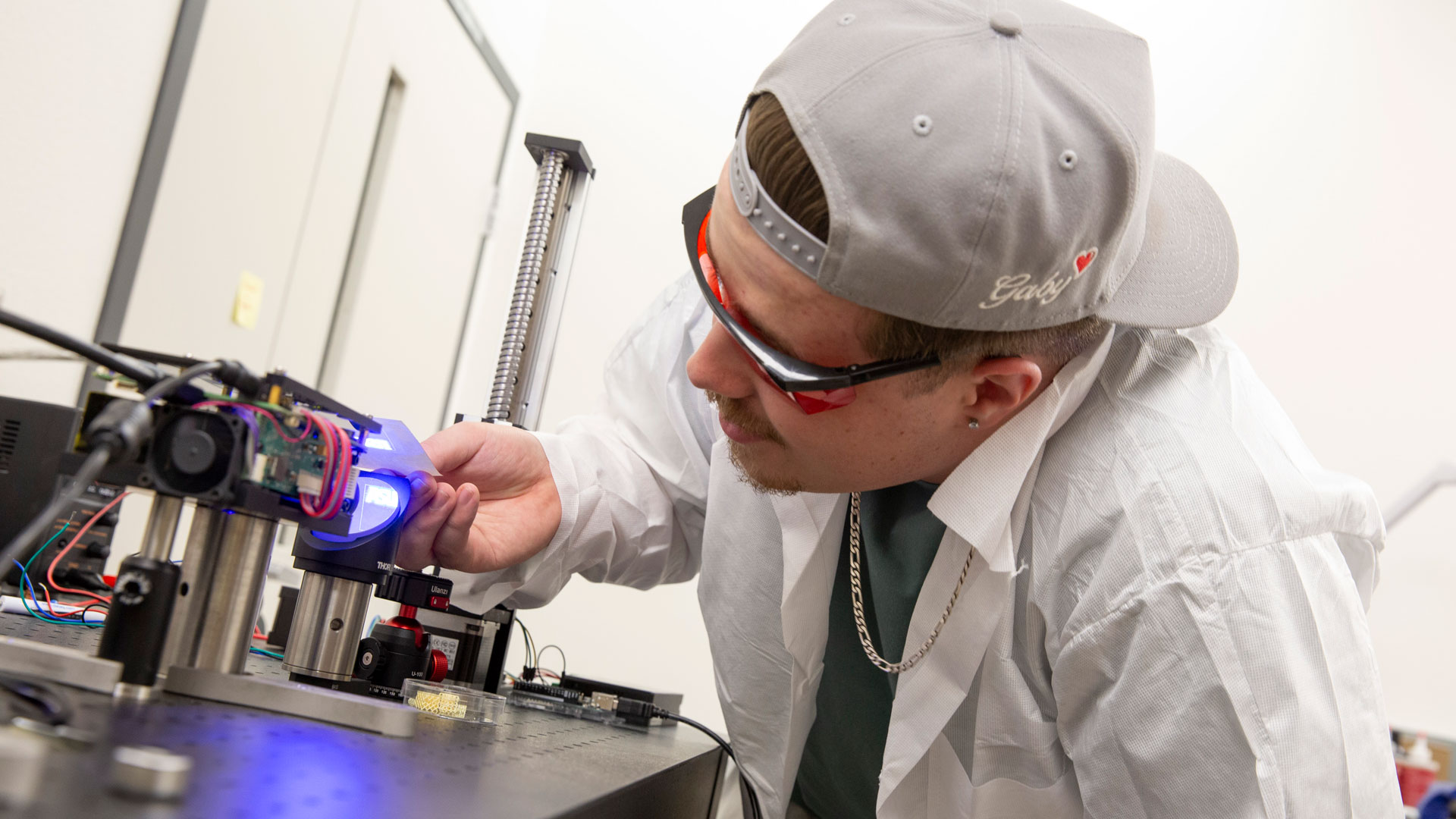

Current mainstream 3D printing processes cannot achieve printing resolutions down to the sub-micron scale without sacrificing manufacturing rates, and the printed 3D microarchitectures are significantly limited by their scalability. Moreover, rapid printing multiple materials is still limited. This research introduces micro-continuous liquid interface printing (μCLIP) technology, which enables the rapid creation of complex, multi-material micro-structures through an active material exchange process. This approach allows structures to vary in density, material properties, and structural integrity. If successful, it could enhance technologies such as regenerative medicines, soft robotics, and smart sensing.

Mentor: Xiangfan Chen

Featured project | Fall 2024

Arick Nitzsche likes studying manufacturing engineering because it’s all about continuous improvement, making things run efficiently and ensuring cost-effectiveness. As a junior, he got involved in the FURI program to work on research that aligns with his interests. With faculty mentor Xiangfan Chen, an assistant professor of manufacturing engineering, Nitzsche’s project aims to improve the process of 3D printing complicated shapes while also using multiple types of materials.

What made you want to get involved in FURI, and why did you choose the project you’re working on?

I wanted to get involved in this program because it allowed me to do things as an undergraduate student that most others are not able to do. I wanted to be able to do real and meaningful research in a lab.

I chose the project I am working on because additive manufacturing is a fascinating topic to me. The more I learn about 3D printing the more I realize how versatile 3D printing is.

How will your research project impact the world?

My engineering research project will impact the world by speeding up 3D printing and allowing for the creation of more complex objects made from different materials at once. This could lead to better technology in areas like medical devices, smartphones and semiconductors. Overall, 3D printing can be applied to any field to find new creative ways to implement technology. For example, 3D printing little robots using a flexible material with very small magnets inside of it allows for noninvasive surgery to occur on patients using magnetic fields that would otherwise be invasive.

Have there been any surprises in your research?

There have definitely been some surprises in my research. The project I am working on is a lot more complicated than I realized at the beginning. However, I do not think that is a bad thing. Before this I was oblivious to how many fields could be improved using 3D printing and the vast amount of materials that could be used to create various products or machines.

How do you see this experience helping with your career or advanced degree goals?

This experience will help me with my career as I have learned a lot more about the field I am interested in. I have been able to get my foot in the door and get some insights into how the industry functions. I have also learned more basic skills and encountered new machines and tools I never knew existed before I entered the FURI program.

Why should other students get involved in FURI?

I think other students should get involved in this program because it opens up your world to future opportunities. By joining FURI you are setting yourself up for success. Not only are you doing that but you can get hands-on experience in a topic you are interested in with the financial support you need to get real answers to the problem at hand. Overall, it’s a great experience that will give you more than you could ask for.