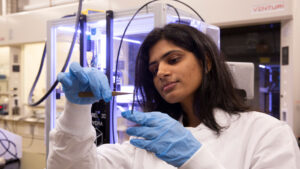

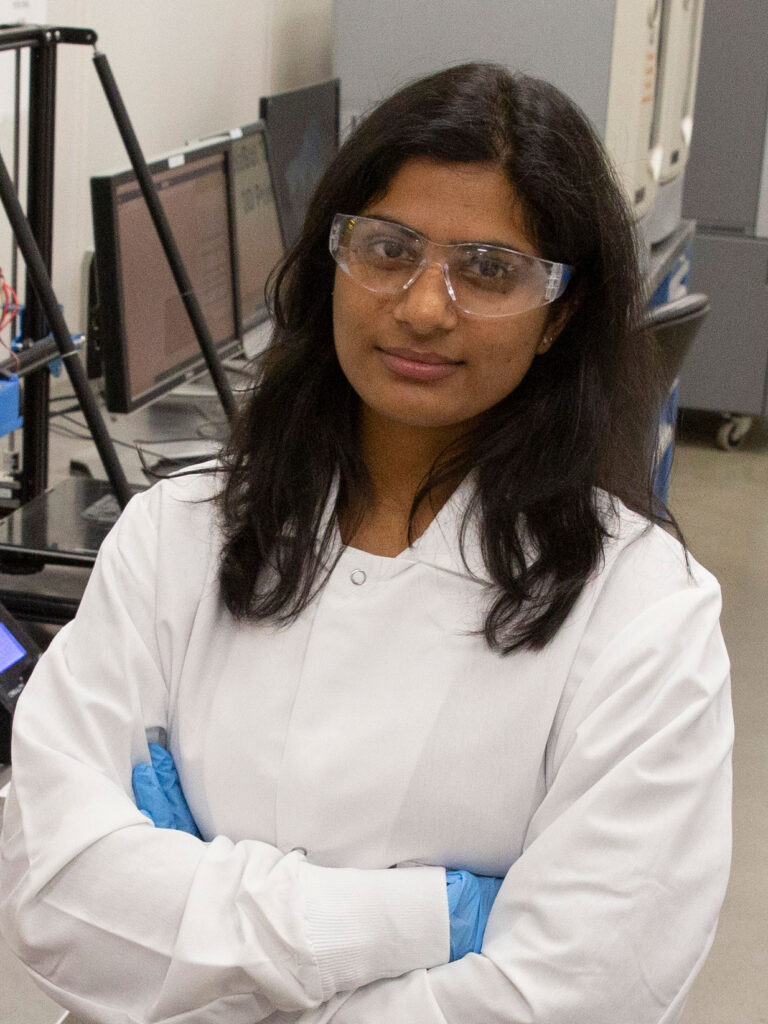

Mounika Chowdary Kakarla

Materials science and engineering

Hometown: Kakinada, Andhra Pradesh, India

Graduation date: Fall 2021

MORE | Summer 2021

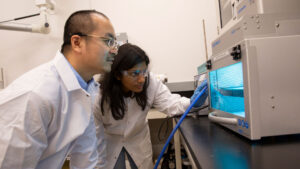

Manufacture of 3D Printed Composite Structures via Multiphase Direct Ink Writing

Although additive manufacturing is a rapid prototyping technology, the printing resolution for most commercial printers are limited to microscales, especially the lack of high-resolution structural control in the case of polymer/nanocomposites. This research study demonstrated the efficient technology for 3D printing nanocomposites using multiphase direct ink writing (MDIW), a printer designed and assembled in-house. By matching the viscosity of the pure PVA solution and PVA/carbon nanotubes solution, layers in the order of 2n+1 (where n is the number of multipliers in the printing system) are printed and the structure showed the improved strength, modulus, and toughness than the conventional ones.

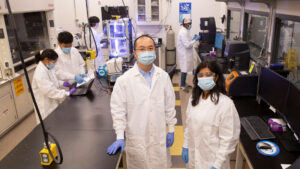

Mentor: Kenan Song

Featured project | Summer 2021

Materials science and engineering graduate student Mounika Karkarla is developing a new method of 3D printing that can be used for biomedical scaffolds and soft robotics in a MORE research project with Assistant Professor Kenan Song. She is thankful for the opportunity to work with her mentor and labmates, and she says research helped her get through the COVID-19 pandemic.

What made you want to get involved in MORE and the project you’re working on?

My mentor suggested I apply for the MORE program to share about our research. The idea of modifying material in every way possible is interesting and it challenged my skills.

How will your engineering research project impact the world?

We are expecting to change the 3D printing world by introducing a composite printing concept. I think now we can say we did, as we successfully demonstrated our concept.

Did you have a particular “aha!” moment during your research?

Yes! Our research is all about those tiny “aha!” moments, from selecting the right polymer to getting the properties we wanted them to exhibit. But when we had a paper published in a reputable journal, it was a memorable moment for me.

How do you see this experience helping with your career?

I learned many material properties, how they behave and change and also how to operate complicated machines. Due in part to the experiences I’ve gained conducting MORE research, I successfully landed internship opportunities at ON Semiconductor and Intel Corporation.

What is the best advice you’ve gotten from your faculty mentor?

Challenge and disappointment are the things I have to remember while doing research. They keep my feet on the ground while aiming for the sky.

Why should other students get involved in MORE?

It gives students confidence to do hands-on research and the funding will help provide materials to experiment with. I wish more students knew about it.