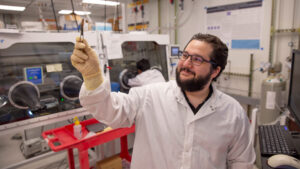

Jacob Burrows

Electrical engineering

Hometown: Batavia, Illinois, United States

Graduation date: Spring 2024

FURI | Fall 2023

Low-Temperature Reduction of Metal Oxide Semiconductors Using Open-Air Plasma

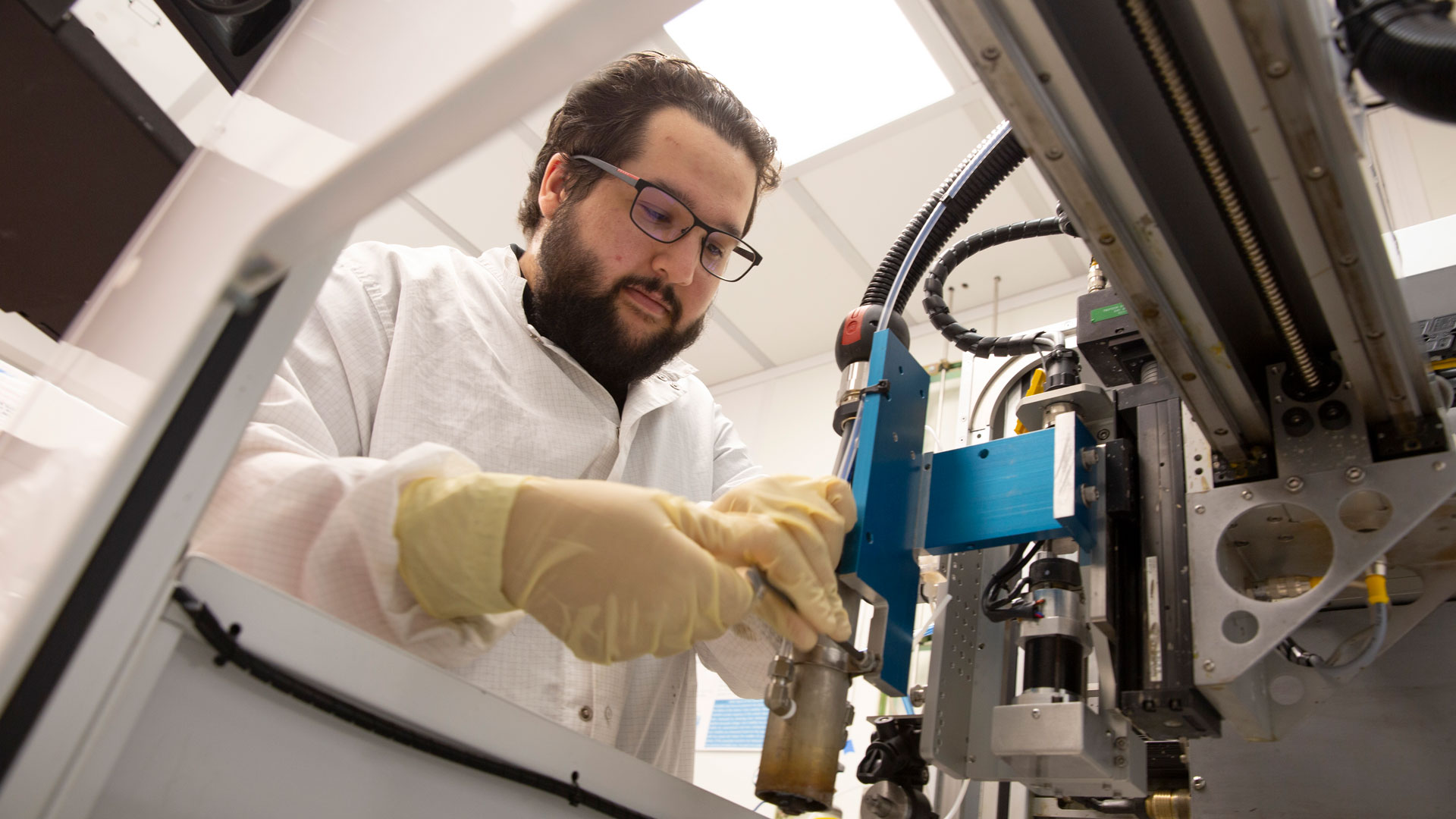

This research proposal focuses on using open-air plasma technology to reduce metal oxidation in semiconductor components that can degrade performance, specifically in printed circuit boards (PCBs). The open-air plasma system utilizes a blown arc discharge to generate reactive species and convective heat, enabling rapid oxide reduction on metal surfaces (i.e., copper, tin, and nickel). Characterization techniques like optical microscopy, X-ray photoelectron spectroscopy, and resistance measurements will evaluate the surface structure, purity, and electrical properties of the foils. The research seeks to optimize the plasma treatment process and assess its impact on semiconductor manufacturing, improving device performance and reliability.

Mentor: Nick Rolston

Featured project | Fall 2023

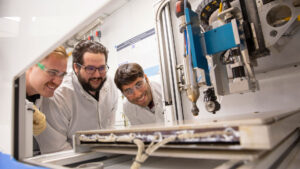

Electrical engineering senior Jacob Burrows is investigating how open-air plasma technology can reduce metal oxidation, which negatively affects performance and longevity when it is present on semiconductor devices’ printed circuit boards. He has been working on this FURI research project under the mentorship of Nick Rolston, an assistant professor of electrical engineering, in the summer and fall of 2023 and was sponsored by the semiconductor foundry TSMC. Sponsorship provides additional funding for undergraduate students to conduct exceptional semiconductor-related research.

Why did you choose the project you’re working on?

Ever since my early academic exposure to electrical engineering, the intricacies of semiconductor manufacturing piqued my interest. The ability of these tiny components to power entire devices and systems seemed almost magical, driving my curiosity to understand the behind-the-scenes processes.

In the electrical engineering curriculum, we delve into the fundamental principles behind semiconductors, their properties and their roles in electronic devices. However, the comprehensive understanding of semiconductor manufacturing processes, from wafer fabrication to packaging, is often explored in specialized courses or through self-directed learning. My interest in the manufacturing aspect is a supplementary deep dive, building upon the foundational knowledge from my major.

How will your engineering research project impact the world?

Traditionally, semiconductor devices and printed circuit boards suffer from the gradual degradation of their metal components, primarily due to oxidation. This oxidation can lead to reduced performance, increased energy consumption and shortened device life span. By researching technologies that mitigate metal oxidation, we aim to enhance the overall efficiency and longevity of these devices, making them more sustainable and reducing electronic waste over time.

Reducing metal oxidation primarily preserves the integrity and efficiency of the metal components within semiconductor devices and printed circuit boards. Oxidation can lead to the formation of non-conductive layers on metal surfaces, which can impede electronic signals, reduce energy efficiency and even cause device failures. By curbing this oxidation, devices can maintain optimal performance levels for more extended periods, ensuring that they function as intended and don’t require frequent replacements or repairs.

Have there been any surprises in your research?

One major surprise was understanding the intricacies and nuances of the X-ray photoelectron spectroscopy, or XPS, tool. XPS has been particularly central to our testing processes. The XPS tool allows us to analyze the surface chemistry of the semiconductors by detecting the energy and number of electrons that escape from the top layers of the material when they are exposed to X-rays. This provides invaluable insight into the composition and electronic state of the materials we are examining. Additionally, we use multimeters for basic diagnostic tasks, like measuring various electrical properties such as voltage, current and resistance. A significant part of our research also involves setting up and optimizing the plasma machine for our open-air plasma experiments.

How do you see this experience helping your career?

While my aspirations may evolve with time and experience, I currently aim to work in semiconductor manufacturing or design, particularly in roles that bridge the gap between research and commercial production. In the long run, I envision myself leading research and development teams to develop next-generation semiconductor technologies, fostering innovation that can propel the electronics industry forward and make a positive impact on society. Conducting this research has been a treasure trove of experience and skill acquisition, specifically my technical proficiency, problem-solving, project management, collaboration and innovation skills.

What is the best advice you’ve gotten from your faculty mentor?

During the early stages of my research, I was working on optimizing the parameters for our open-air plasma technology. One particular experiment involved using a specific combination of power levels and exposure times to enhance the quality of the semiconductor surface. However, when the actual experiment was conducted, not only did it not yield the expected improvements, but it also degraded the semiconductor metal surface. At first, I was disheartened, feeling like I had wasted precious time and resources. However, recalling my faculty mentor’s advice that “no experiment is a failure,” I began to analyze the results more critically. While the initial objective was not met, the unexpected outcome provided valuable insights into the limitations of the technology under certain conditions. This “failure” proved instrumental in redefining our approach and parameters for subsequent experiments, ensuring that we avoided similar pitfalls.

Why should other students get involved in FURI?

Engaging with FURI offers students unparalleled access to a vibrant community of researchers and industry experts, facilitating meaningful networking opportunities. But more than that, FURI provides a hands-on experience that deepens one’s comprehension of their chosen field.